Views: 0 Author: Site Editor Publish Time: 2026-01-05 Origin: Site

Spiral fin tubes are a specialized type of heat exchanger tube designed to enhance heat transfer efficiency. Unlike traditional straight fin tubes, which have fins arranged parallel to the tube surface, spiral fin tubes feature helical or spiral-shaped fins wrapped around the tube. This unique design increases the surface area and improves fluid flow dynamics, leading to more efficient heat dissipation. The spiral structure not only boosts heat transfer but also reduces the risk of fouling, making these tubes particularly effective in applications where space is limited or where heat exchange needs to be maximized. Spiral fin tubes are widely used in industries such as HVAC, refrigeration, power generation, and petrochemicals, offering an ideal solution for both space-constrained environments and high-performance heat exchange systems.

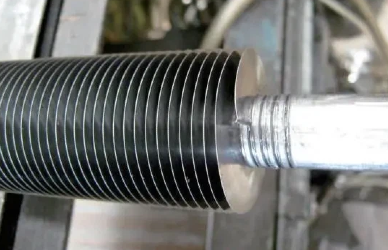

Spiral fin tubes are a type of heat exchanger tube with fins wound around the tube in a helical, spiral shape. This design is distinct from traditional straight fin tubes, where the fins are placed parallel to the tube’s surface. The spiral fins are typically made from materials such as aluminum, copper, or stainless steel, and they increase the surface area of the tube, which is essential for efficient heat transfer. The helical arrangement of the fins improves fluid flow dynamics and helps prevent the accumulation of debris or fouling, which can often occur with straight fins.

Spiral fin tubes are engineered to offer several key benefits that make them highly efficient in various applications:

Helical Shape: The spiral design allows for enhanced heat transfer by increasing the surface area in contact with the fluid. This larger surface area promotes better thermal conduction and heat dissipation.

Improved Fluid Flow: The spiral arrangement of the fins helps create turbulence in the fluid flowing around the tube, which improves heat transfer efficiency. This is especially important in applications where high heat exchange rates are required.

Compact Design: The helical fins can maximize heat exchange in a smaller space compared to other types of fin tubes. This makes spiral fin tubes ideal for use in environments with limited space, such as compact heat exchangers or small cooling systems.

Resistance to Fouling: The spiral shape reduces the likelihood of dirt and other particles settling on the surface of the fins, as the flow of fluid around the helical fins helps keep them cleaner. This increases the longevity and performance of the tube.

High Performance in High-Heat and High-Pressure Environments: Spiral fin tubes can efficiently handle high-temperature and high-pressure applications, particularly when made from durable materials like stainless steel.

Spiral fin tubes are widely used in industrial heat exchangers due to their exceptional ability to improve heat transfer efficiency. The helical design of the fins increases the surface area for heat exchange, allowing for better thermal conduction between fluids. The increased surface area and enhanced fluid turbulence lead to higher heat transfer rates, making spiral fin tubes ideal for applications where efficient cooling or heating is essential. In industries such as oil and gas, HVAC, and power plants, spiral fin tubes help improve the performance and energy efficiency of heat exchangers, reducing operational costs and enhancing system reliability.

In HVAC (Heating, Ventilation, and Air Conditioning) and refrigeration systems, spiral fin tubes play a crucial role in boosting cooling performance. These systems require effective heat dissipation, and the spiral design helps optimize the transfer of heat from the refrigerant or air to the surrounding environment. The helical fins promote better fluid flow, which not only increases heat exchange efficiency but also reduces the chances of system fouling, ensuring that the equipment operates smoothly for longer periods. Spiral fin tubes are therefore essential in air conditioning units, industrial refrigeration, and commercial cooling systems, where space and cooling capacity are critical.

In power generation, spiral fin tubes are used in steam generators, boilers, and other thermal systems to enhance heat exchange efficiency. Power plants require efficient heat transfer to convert thermal energy into mechanical energy, and the spiral fin tube’s design maximizes the surface area for better heat dissipation. The improved thermal conductivity and reduced fouling properties of spiral fin tubes help power generation systems achieve higher energy efficiency and reduced maintenance costs. Their robust construction also makes them suitable for high-temperature and high-pressure environments typically found in steam boilers and other thermal power systems.

Spiral fin tubes are particularly effective in the petrochemical and chemical processing industries, where optimal heat transfer is required in corrosive environments. Refineries and chemical plants often operate under extreme conditions, with high temperatures, pressures, and exposure to corrosive chemicals. The durable materials used in spiral fin tubes, such as stainless steel, make them highly resistant to corrosion and able to withstand these harsh conditions. The spiral design helps maintain high heat transfer efficiency while preventing debris and particles from clogging the surface, which is essential for maintaining system performance in demanding environments like refineries, chemical reactors, and cooling towers.

The helical or spiral design of fin tubes significantly enhances heat transfer efficiency. The spiral shape increases the surface area of the tube, which allows for more heat to be transferred from the fluid inside the tube to the surrounding environment. Additionally, the spiral arrangement promotes better fluid flow dynamics, which creates turbulence that further improves heat exchange. This makes spiral fin tubes ideal for applications where rapid or efficient heat dissipation is critical, such as in heat exchangers, refrigeration systems, and HVAC applications.

One of the key benefits of spiral fin tubes is their space efficiency. The compact nature of the spiral design allows for a higher heat transfer rate in a smaller area compared to traditional straight fin tubes. This makes spiral fin tubes perfect for applications where space is limited, such as in small heat exchangers or cooling systems. Their ability to provide high performance in a compact form factor makes them a popular choice for industries where space constraints are a concern, including in air conditioning units and other space-limited systems.

Spiral fin tubes are designed to withstand challenging industrial environments, including exposure to high temperatures, pressures, and corrosive substances. Materials such as stainless steel, aluminum, and copper alloys are often used in the construction of spiral fin tubes to provide superior resistance to corrosion and wear. This corrosion resistance ensures that the tubes maintain their performance and longevity even in harsh conditions found in industries like petrochemicals, power generation, and marine applications. The durability of spiral fin tubes reduces the need for frequent maintenance or replacement, making them a cost-effective solution in long-term operations.

Spiral fin tubes differ from regular fin tubes due to their helical design. Unlike the parallel fins in regular tubes, the spiral fins increase surface area and improve fluid flow dynamics, leading to better heat transfer efficiency and reduced fouling.

Spiral fin tubes are preferred because their increased surface area and enhanced fluid movement improve heat exchange efficiency. The spiral design creates better turbulence, making them ideal for high-performance heat exchangers in industrial applications.

Yes, spiral fin tubes are suitable for high-temperature applications, especially when made from heat-resistant materials like stainless steel or copper alloys. These materials can handle elevated temperatures without compromising the tube's structural integrity.

Yes, the compact spiral design allows for efficient heat transfer in small spaces. This makes them ideal for systems with space constraints, such as compact heat exchangers and cooling units.

Spiral fin tubes are highly versatile and efficient, making them an essential component in various industries. Their unique helical design significantly improves heat transfer by increasing surface area and optimizing fluid flow dynamics, which results in better thermal performance. This enhanced efficiency makes spiral fin tubes particularly effective in applications such as industrial heat exchangers, HVAC systems, refrigeration units, power generation, and chemical processing. Their compact design allows for high heat exchange rates in space-limited environments, making them ideal for systems with tight space constraints. Additionally, the materials used in spiral fin tubes, such as stainless steel and copper alloys, offer excellent corrosion resistance and durability, allowing them to perform reliably in harsh, high-temperature, and high-pressure conditions. Because of these benefits, spiral fin tubes are the preferred choice for applications that require both superior heat transfer efficiency and long-term durability. Their combination of performance, compactness, and robustness ensures that they continue to meet the demanding needs of various industries, providing long-lasting solutions in both commercial and industrial applications.